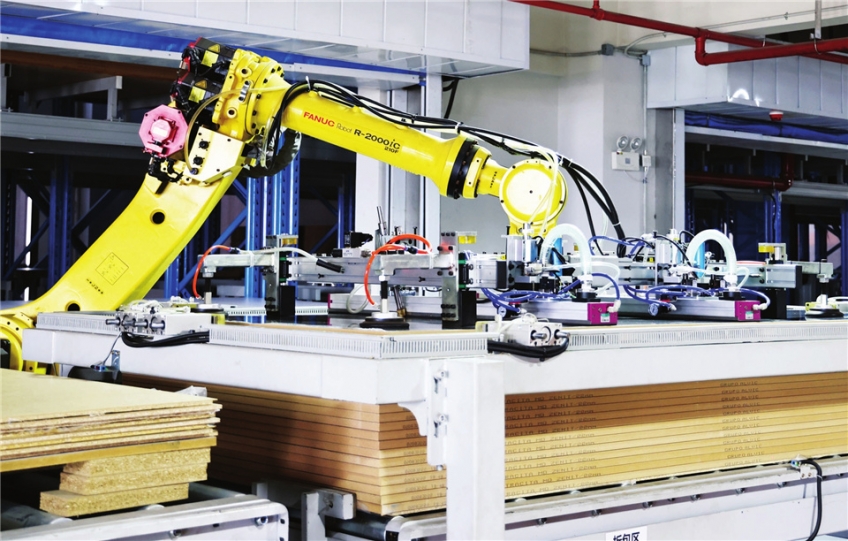

A manipulator is picking needed panels from a stereoscopic storage. (Photo/Wen Bo)

On the morning of March 23, in the intelligent workshop of Guangdong Vifa Customized Home Furnishings Co Ltd (Vifa), production was in full swing for over 200 orders.

Now digitalization has enabled whole chain collaboration of the company, and multiple-batch, small-lot customization can be realized through intelligent manufacturing, according to Lei Wen, director of Vifa and general manager of Vifa's Zhongshan base. With a full-process intelligent workshop, Vifa has doubled its production and reduced its labor by one third.

Through continuous investment in innovation and R&D and persistent efforts on digital and intelligent transformation, Vifa is no longer a traditional home furnishing manufacturer, but a specialized, refined, distinctive and innovative "small giant" enterprise accredited by the Ministry of Industry and Information Technology, and its intelligent workshop was selected as one of the model digital and intelligent manufacturing workshops of Zhongshan in 2022.

Vifa's output value stood at 300 million yuan before 2020, but was doubled in 2022 after putting its new digital and intelligent workshop into operation.

In addition, Vifa invests about 5% of its output value in R&D every year. The company has obtained a total of 220 patents, including 4 patents for invention and 185 utility model patents.

Police Registration Number: 44200002442868

Website ID: 4420000052

Sponsored by: Office of Zhongshan Municipal People's Government

Technical Support: Information Center of Zhongshan

Without written authorization from Zhongshan Municipal People’s Government, the content of the site shall not be republished or used in any form.

About Us | Site Map| Privacy Statement| Contact us